NCI has a technical staff comprised of highly experienced food scientists, processing technologists, and project managers. Our team has the experience and resources to bring your vision to life; from start to finish we partner with you through the process, creating a concise and clear experience to help you scale-up your product development right to your factory and consumer production.

Our team operates under full confidentiality so your information and products belong solely to you. We do not publish, release, or share client information nor charge overhead, which may happen with academic institutions.

What We Provide

Consulting

Our highly qualified technical team is able to serve various businesses with consulting solutions specific to you.

Processing & Product Development

We can assist in the processing or testing of an ingredient or new product.

Testing Services

With our wide array of technology, we can test and evaluate multiple ingredients and food products.

Explore Our Technical Facilities

Our specialized labs and facilities provide hands-on support for a variety of projects.

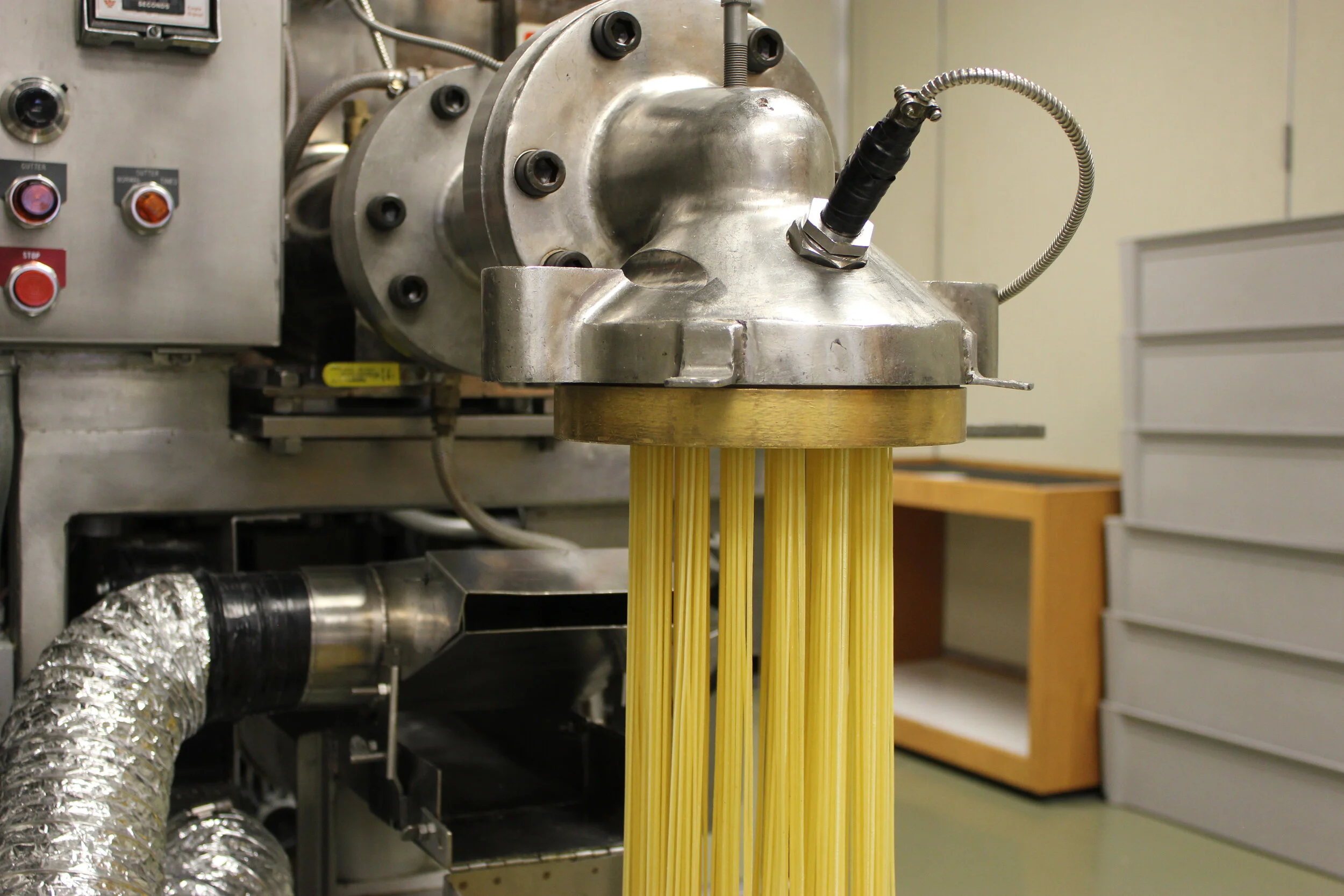

The Pasta Processing Laboratory is a food safe space equipped to demonstrate the impact of raw materials and processing on end product quality for traditional pasta, ravioli and gluten-free pasta.

The Soy Foods Laboratory provides a fully food-grade space for developing, testing, and producing soy-based and plant-based foods, including soymilk, tofu, natto, tempeh, miso, and plant-based beverages.

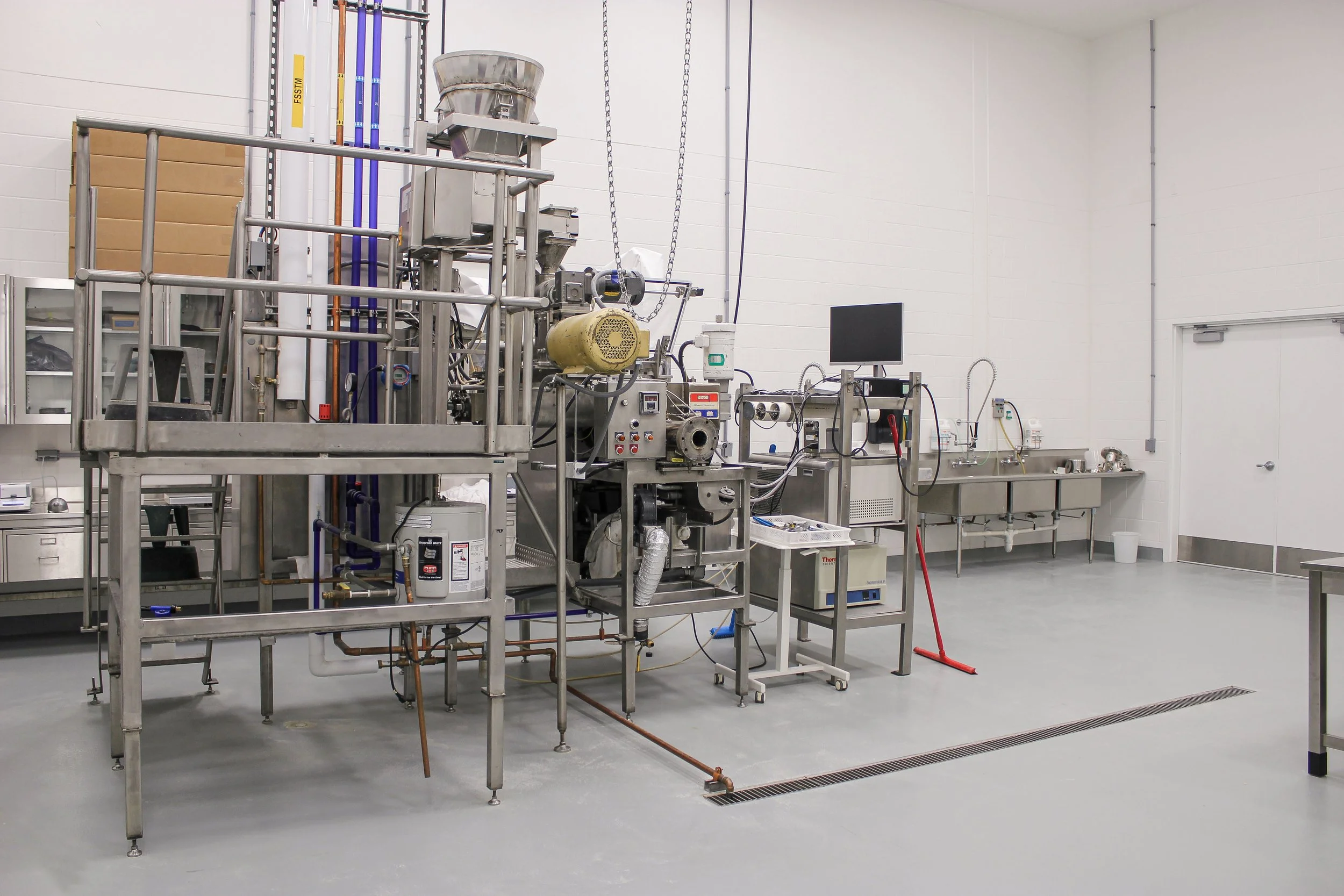

The Extrusion Laboratory is equipped with a Wenger TX-52 twin-screw extruder for demonstrating the impact of raw materials and processing conditions on the organoleptic, textural, and nutritional characteristics of these foods.

The Baking Laboratory is a state-of-the-art facility dedicated to instructional use. Our lab supports a wide range of baked goods, including pan breads, tortillas, buns, artisan breads, cookies, cakes, and more.

The Rheology Laboratory is equipped to evaluate oilseeds, whole grain, milled products, and finished products in a quality control environment with an array of equipment and instruments.

The Analytical Laboratory provides comprehensive testing services to evaluate the quality, safety, and nutritional profile of flour, grain-based products, and food ingredients.

The Pilot-Scale Milling room is capable of milling spring wheat, winter wheat, or durum wheat into refined flour, whole wheat flour, or semolina, respectively.

The Oilseed Processing Laboratory has full pilot-scale capability for oilseed extraction on a wide variety of crops.

The Stone Mill Room embraces the growing trend of producing nutritionally rich stone-milled and whole grain flours.

The Sensory Kitchen and separate sensory testing room is used for individual consumer sensory panels.

The Feed Production Center is a hub for education and technical assistance in feed mill management and manufacturing technologies, serving both domestic and international clients.